Particular consideration is necessary for setting up greatest microbial action stages for Ingesting Water as the water is commonly sent to the ability inside a issue above which the user has small Command. High microbial stages in Consuming Water might be indicative of a municipal water procedure upset, broken water principal, or inadequate disinfection, and therefore, prospective contamination with objectionable microorganisms. Utilizing the advised microbial enumeration methodology, a reasonable maximum motion amount for Consuming Water is 500 cfu for every mL.

TYPES OF WATER You can find many alternative grades of water used for pharmaceutical purposes. Various are explained in USP monographs that specify employs, appropriate methods of preparing, and high quality characteristics. These waters can be divided into two basic types: bulk waters, which are usually generated on internet site where by They're used; and packaged waters, which happen to be made, packaged, and sterilized to preserve microbial excellent through their packaged shelf lifetime.

Likewise, using a extra stringent type of water, when not required, could result in elevated prices. Increase while in the amplified scrutiny with the at any time-shifting regulatory landscape, and it will become very important to have a complete comprehension of the water a procedure calls for.

At Rx Return Expert services, we are devoted to supplying top rated-notch pharmaceutical squander management answers to a diverse array of industries. Our mission should be to streamline the disposal process when making sure the best amount of compliance, security, and shopper pleasure.

With a significant eye all through the style and design and engineering procedure, our water for injection devices are constructed to constantly and reliably develop the WFI you will need.

The distribution design should involve the placement of sampling valves during the storage tank and at other spots, such as inside the return line from the recirculating water process. Exactly where possible, the key sampling web pages for water really should be the valves that produce water for the factors of use. Immediate connections to procedures or auxiliary gear ought to be built to reduce reverse stream in to the managed water method.

Our adaptable solutions and skilled staff make certain that we can easily efficiently handle your one of a kind disposal wants, regardless of your discipline. Speak to us currently to learn the way we can help you.

In water programs, microbial retentive filters might be used downstream of device functions that have a tendency to launch microorganisms or upstream of device operations which are sensitive to microorganisms. Microbial retentive filters may be used to filter water feeding the distribution technique. It ought to be observed that regulatory authorities let using microbial retentive filters within distribution programs or maybe at use details if they happen to be properly validated and are appropriately preserved. A degree-of-use filter must only be meant to “polish” the microbial top quality of an or else properly-taken care of program instead of to serve as the first microbial Management device. The efficacy of process microbial Management steps can only be assessed by sampling the water upstream of your filters. As an additional measure of safety, in-line UV lamps, appropriately sized to the stream charge (see Sanitization), may be used just upstream of microbial retentive filters to inactivate microorganisms prior to their seize by the filter. This tandem solution has a tendency to enormously hold off possible microbial penetration phenomena and will significantly extend filter assistance lifetime. Ultraviolet Gentle The use of low-force UV lights that emit a 254-nm wavelength for microbial Command is talked about beneath Sanitization, but the appliance of UV light in chemical purification is also rising.

Manufacture of pharmaceutical water employs sequential unit operations (processing measures) that address specific water excellent attributes and guard the Procedure of subsequent remedy actions. A typical analysis procedure to choose an suitable water high-quality for a selected pharmaceutical function is shown in the decision tree in Figure two. This diagram can be used to help in defining requirements for unique water employs and in the selection of device operations. The ultimate device operation used to produce Water for Injection is limited to distillation or other processes equivalent or outstanding to distillation in the removing of chemical impurities and also microorganisms and their elements. Distillation has an extended record of reputable performance and might be validated for a unit Procedure for your creation of Water for Injection, but other systems or mixtures of systems may be validated as being equivalently efficient. Other technologies, like ultrafiltration adhering to other chemical purification course of action, can be ideal within the production of Water for Injection if they can be proven by way of validation to generally be as successful and trusted as distillation. The advent of new resources for older technologies, including reverse osmosis and ultrafiltration, that make it possible for intermittent or ongoing Procedure at elevated, microbial temperatures, clearly show guarantee for a legitimate use in making Water for Injection.

Membrane ultrafiltration serves being a membrane separation method that efficiently separates quite wonderful particles or suspended make a difference, ranging in size from 0.

However, preparing Recommendations For most reagents had been carried ahead with the innovator's laboratories on the initially launched monograph for a particular USP&#a hundred and fifty;NF posting or common check chapter. The standard of the reagent water described types of water used in pharmaceuticals in these assessments may perhaps mirror the water quality designation with the innovator's laboratory. These unique water designations may have originated with no innovator's awareness of the prerequisite for Purified Water in USP–NF checks.

. It might also be used in other programs, which do not need particulate issue requirements, in which bulk Water for Injection or Purified Water is indicated but where use of a validated water method is not sensible or where by fairly more substantial portions than are offered as Sterile Water for Injection are wanted. Sterile Water for Inhalation— Sterile Water for Inhalation (see USP monograph) is Water for Injection that is certainly packaged and rendered sterile and is meant for use in inhalators and within the planning of inhalation solutions.

Although filtration functions well in principle, it is comparatively costly for top throughputs given that they require common shifting to stop blockage and “improve-through.” Due to this, making use of 0.22 μm filters to regulate contamination in water used for product or service manufacture is frowned on. Filters needs to be used only previous to the distribution method.

Ozone more info is utilized for disinfecting consuming water in the ecu municipal water industry for over a century. Several water providers utilize ozone generators with capacities reaching as many as 100 kilograms for every hour.

Sam Woods Then & Now!

Sam Woods Then & Now! Elin Nordegren Then & Now!

Elin Nordegren Then & Now! Susan Dey Then & Now!

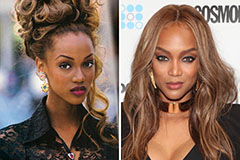

Susan Dey Then & Now! Tyra Banks Then & Now!

Tyra Banks Then & Now! Mike Smith Then & Now!

Mike Smith Then & Now!